How Can AI Benefit Production Efficiency?

Updated 08 Sep 2024 by Nex AI Team

Introduction

Artificial Intelligence (AI) is revolutionizing various sectors, and manufacturing is at the forefront of this transformation. AI encompasses a range of technologies, including machine learning, computer vision, and natural language processing, that enable machines to mimic human intelligence and perform tasks autonomously.

In the manufacturing industry, AI is being employed to optimize production lines, enhance precision, and drive innovation. From automating repetitive tasks to providing real-time data analysis, AI technologies are significantly altering the traditional manufacturing landscape, making processes more efficient and less prone to errors.

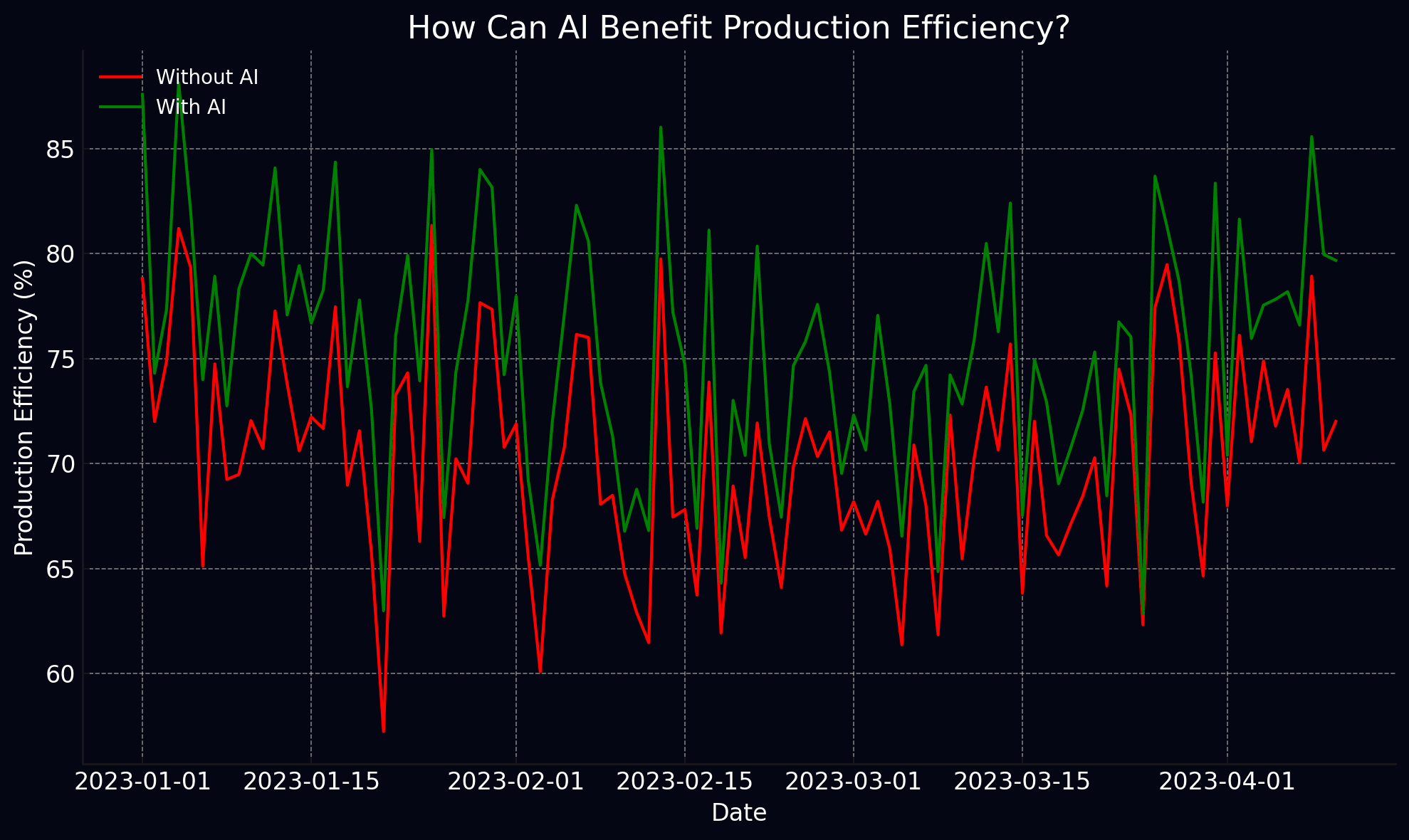

Production efficiency is a critical factor for the success of any manufacturing operation. Efficient production processes not only reduce operational costs but also improve product quality and speed up time-to-market. In an increasingly competitive market, manufacturers are under constant pressure to maximize output while minimizing waste and downtime.

This is where AI comes into play. By leveraging advanced algorithms and predictive analytics, AI can help manufacturers achieve higher levels of efficiency and productivity. For instance, predictive maintenance powered by AI can foresee equipment failures before they occur, thereby reducing unexpected downtimes and extending the lifespan of machinery.

Moreover, the importance of production efficiency extends beyond mere cost savings. Efficient production processes contribute to sustainability by minimizing resource consumption and waste. They also allow manufacturers to be more agile and responsive to market demands, enabling quicker adaptation to changes in consumer preferences and market conditions.

In essence, AI-driven production efficiency not only enhances the bottom line but also supports broader organizational goals such as sustainability, customer satisfaction, and competitive advantage. As we delve deeper into the various ways AI can benefit production efficiency, it becomes evident that the integration of AI into manufacturing processes is not just a trend but a necessity for future success.

How AI Enhances Production Efficiency

Predictive Maintenance

Definition and Benefits

Predictive maintenance leverages AI to forecast and prevent equipment failures, thereby enhancing efficiency and reducing costs. Unlike traditional maintenance approaches, which are either reactive (fixing equipment after it breaks) or preventive (servicing equipment at regular intervals regardless of its condition), predictive maintenance uses AI algorithms to analyze sensor data and predict when maintenance is actually needed. This method ensures that maintenance is performed only when necessary, which minimizes downtime and extends the lifespan of machinery. The benefits of predictive maintenance are numerous: it reduces unexpected equipment failures, lowers maintenance costs, and improves overall operational efficiency.

Real-World Examples

Several leading companies have successfully implemented AI-driven predictive maintenance. For instance, General Electric (GE) uses AI to monitor and predict the health of its industrial equipment. By analyzing data from sensors embedded in machinery, GE's AI systems can predict potential failures and schedule maintenance activities accordingly. This has led to significant reductions in downtime and maintenance costs. Similarly, Siemens has integrated AI into its maintenance processes, resulting in a 20% increase in productivity. These examples demonstrate the transformative potential of AI in predictive maintenance, making it a critical component of modern manufacturing operations.

Quality Control and Inspection

AI in Defect Detection

AI is revolutionizing quality control by automating the inspection process. Traditional quality control methods rely heavily on human inspectors, who may miss defects due to fatigue or human error. In contrast, AI-driven quality control systems use machine vision and deep learning algorithms to identify defects with unprecedented accuracy. These systems can analyze images of products in real-time, detecting even the smallest flaws that might be invisible to the human eye. This not only ensures higher precision in defect detection but also speeds up the inspection process, allowing for faster production cycles.

Improvements in Product Quality

The implementation of AI in quality control leads to significant improvements in product quality. For example, BMW has adopted AI-driven quality control systems to inspect its vehicles. These systems have improved the accuracy of defect detection, ensuring that only high-quality products reach the market. This has resulted in higher customer satisfaction and reduced return rates. Additionally, AI-driven quality control minimizes the production of defective products, thereby reducing waste and lowering production costs. Overall, the use of AI in quality control enhances the reliability and consistency of manufacturing processes, leading to superior product quality.

Supply Chain Optimization

Demand Forecasting

AI plays a pivotal role in optimizing supply chains through improved demand forecasting. Traditional forecasting methods often struggle to accurately predict demand due to the complexity and variability of market conditions. AI, however, can analyze vast amounts of data from various sources, such as sales history, market trends, and economic indicators, to generate more accurate demand forecasts. By predicting demand trends more reliably, manufacturers can better align their production schedules and inventory levels, reducing the risk of overproduction or stockouts.

Inventory Management

AI also enhances inventory management by optimizing stock levels based on real-time data. AI algorithms can analyze data from various points in the supply chain to determine the optimal inventory levels for each product. This helps manufacturers maintain sufficient stock to meet demand without overstocking, which ties up capital and increases storage costs. For instance, Amazon uses AI to manage its vast inventory, ensuring that products are available when customers need them while minimizing excess stock. This has significantly reduced delivery times and operational costs, demonstrating the efficiency gains achievable through AI-driven inventory management.

Production Planning and Scheduling

Real-Time Data Analysis

AI optimizes production planning and scheduling by analyzing production data in real-time. Traditional planning methods often rely on historical data and fixed schedules, which may not account for real-time changes in production conditions. AI, on the other hand, can continuously monitor production processes and adjust plans based on real-time data. This allows manufacturers to respond quickly to changes, such as unexpected equipment failures or shifts in demand, ensuring that production schedules remain efficient and adaptable.

Resource Allocation

Effective resource allocation is crucial for maximizing production efficiency, and AI excels in this area. By analyzing data on resource availability, production requirements, and operational constraints, AI can optimize the allocation of resources such as labor, materials, and machinery. For example, Siemens uses AI to enhance its production planning, resulting in more efficient use of resources and reduced downtime. This not only boosts productivity but also reduces operational costs, making AI-driven resource allocation a valuable tool for modern manufacturing operations.

Conclusion

Artificial Intelligence is fundamentally reshaping the manufacturing landscape by introducing unprecedented levels of efficiency, precision, and innovation. Through advanced algorithms and machine learning, AI optimizes traditional manufacturing processes, driving higher productivity and competitiveness. As we look to the future, the integration of AI with IoT and 5G promises even greater advancements, leading to fully autonomous factories with unparalleled productivity and flexibility. Manufacturers who embrace AI will not only streamline their operations but also foster innovation, enabling them to stay ahead in a rapidly evolving market.